“When the General Manager of Huf Romania S.R.L. came to me for the first time, there still wasn’t so much as an office. We had our first meetings in my living room,” recalls Simona Benea. She became the first employee of Huf Romania S.R.L. in 2006 and has built up the Human Resources department ever since. She never had to invite applicants into her living room, as not long after she had welcomed the high-ranking visitor to her home, Huf acquired its factory in Arad in western Romania.

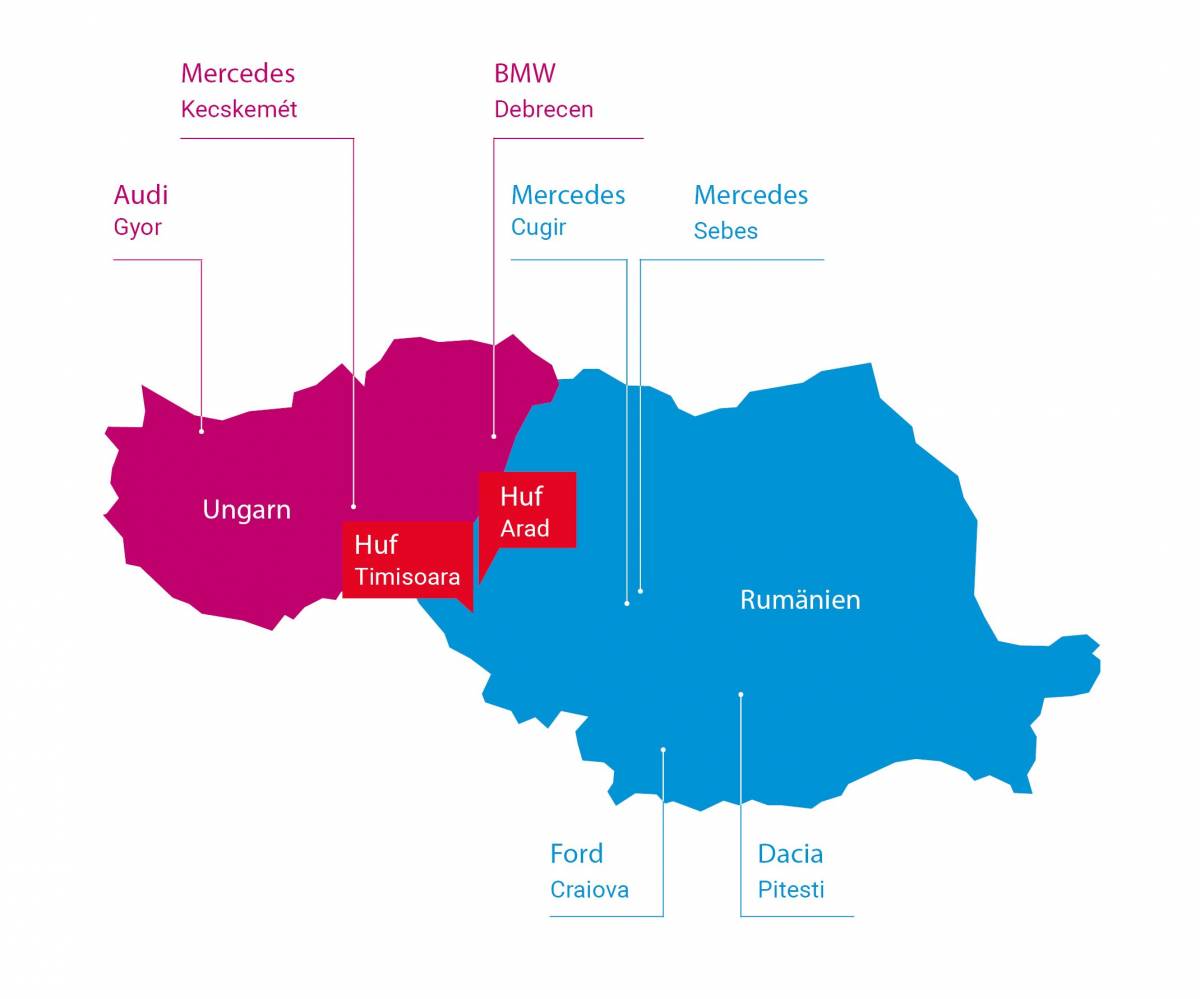

Huf Romania S.R.L. at the hotspot of automotive industry

“The first automotive suppliers began to settle in Romania, and Arad in particular, in the late 1990s, shortly after Renault had bought the Dacia brand,” explains Simona Benea. “The region’s advantages are plain to see. Arad is an industrial city with highly skilled people. It also has excellent infrastructure, which is very important in Romania. Arad is regarded as a gateway to the West and is easily accessible from the freeway and by rail; it also has an international airport.”

A number of other factors influenced the decision to choose this strategically important location, such as low labor costs and the opportunity to continue a long-standing company tradition. Not only does Huf supply its customers with first-class products that meet the very highest standards of quality, but it was well ahead of the curve relative to other automotive suppliers in operating close to where its customers were located, with geographical proximity making it a dependable partner capable of offering short response times and effective services.

Automotive companies focus on Romania and Hungary for subsidiaries

Huf Romania S.R.L. was officially entered on the company register on May 25, 2006. In the years that followed, Romania rapidly flourished to become a hotspot for the automotive industry. In addition to Dacia, which has a factory in Pitesti that Renault has invested heavily in expanding, Ford has a production facility in Romania. The US manufacturer acquired the factory in Craiova in southern Romania from Daewoo in 2008, and the first Ford B-Max rolled off the assembly line there in summer 2012. Mercedes-Benz has operated in Romania since 2001 and got at two sites at Sebes and Cugir.