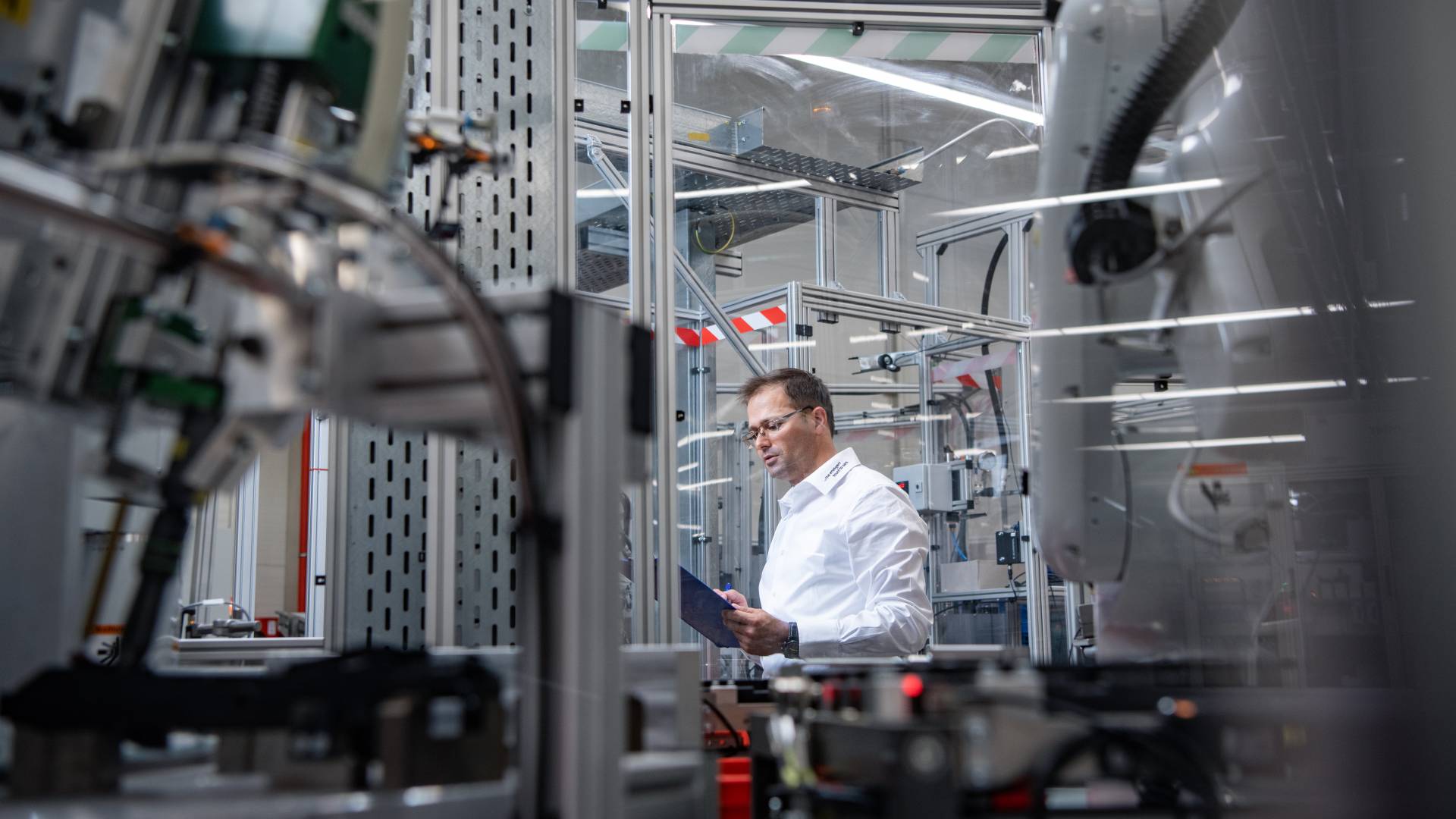

The Huf Production System (HPS) is a structured, tailor-made framework inspired by the Toyota Production System (TPS). It is based on powerful principles and provides an effective set of rules, tools, KPIs and values to optimize our production processes across all locations.

The Huf Production System is based on eight important modules:

- Lean Leadership – impacting all relevant business KPIs (Quality, Cost, Inventory, Delivery, Flexibility, Safety, Morale and Environment.

- Zero Defect Strategy – improved customer satisfaction, reduced cost for scrap/rework, reduced need for firefighting and therefor increased focus on continuous improvement.

- Value Stream – improved value stream flow following the customer takt reduces inventory and process lead times, it leads towards simplified production pull control, smooth, stable and scalable operations.

- Material Management – achieve synchronized material flow, reduces logistic and inventory cost through improved production planning and right size packaging, pull principal leads to efficient material handling.

- Assembly Line management – improved assembly line productivities, increased flexibility, stabilized production.

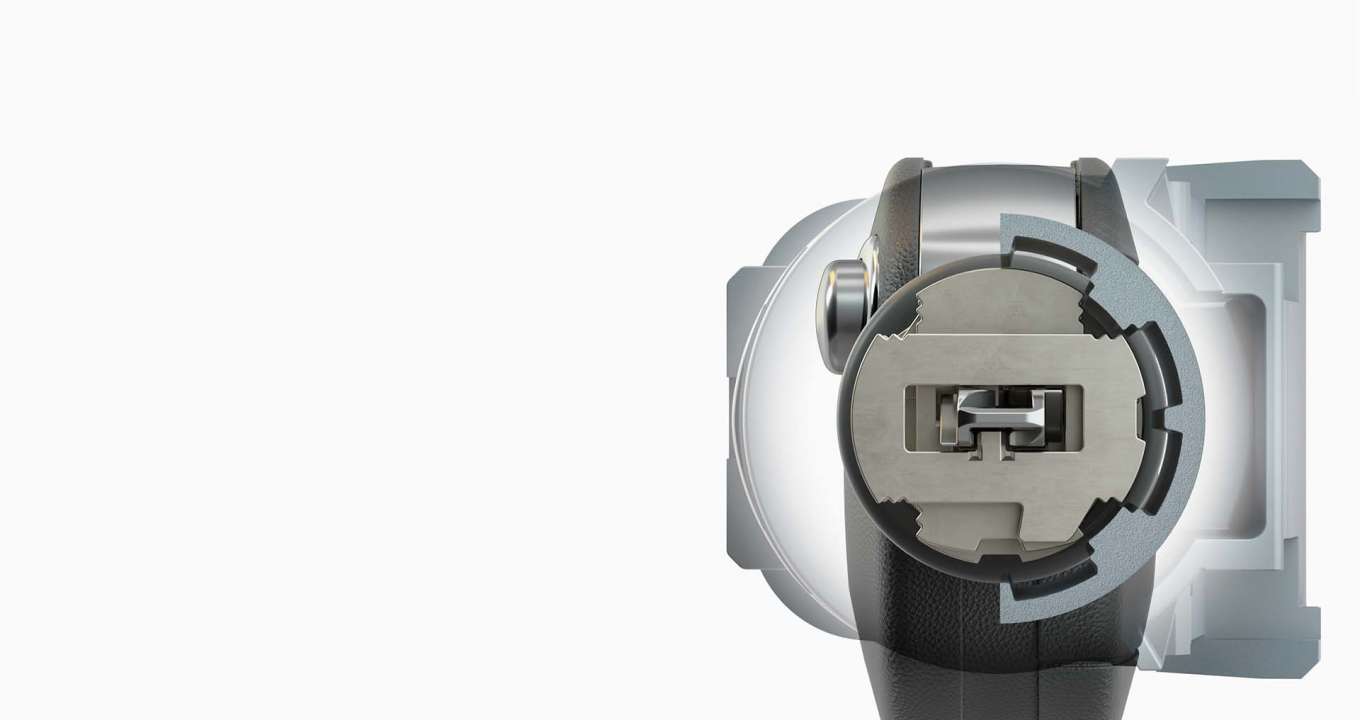

- Equipment Management – improved efficiency and reduced change over times to reduce lot sizes, reduced inventory and increased flexibility. Reduced capex!

- Shop Floor Management – transparency enables the daily management, problem solving and improvement of all relevant shop floor KPIs. Standards allow for the detection of deviations and the elimination of their root causes.

- Supplier Integration – reduced logistics, production and quality cost through increased stability of deliveries to Huf customers, reduced inventories, less excess freight and supply escalations.